Wialon ecosystem

Solutions

Niche products for addressing specific tasks

Vehicle leasing software

Vehicle location tracking for car loans, vehicle leasing, and finance industry

Agriculture fleet tracking

Control crops rotation and field works with Hecterra

Delivery fleet management

We developed Logistics service for you to manage delivery operations

Driver behavior monitoring

Eco Driving – the solution to monitor driving quality

Fleet maintenance management

The web application to plan, control, and record expenditures for maintenance

Field employee tracking

WiaTag turns a smartphone into a GPS tracker and allows controlling field operations and mobile staff performance

Public transportation management

NimBus is designed to control fixed routes vehicles

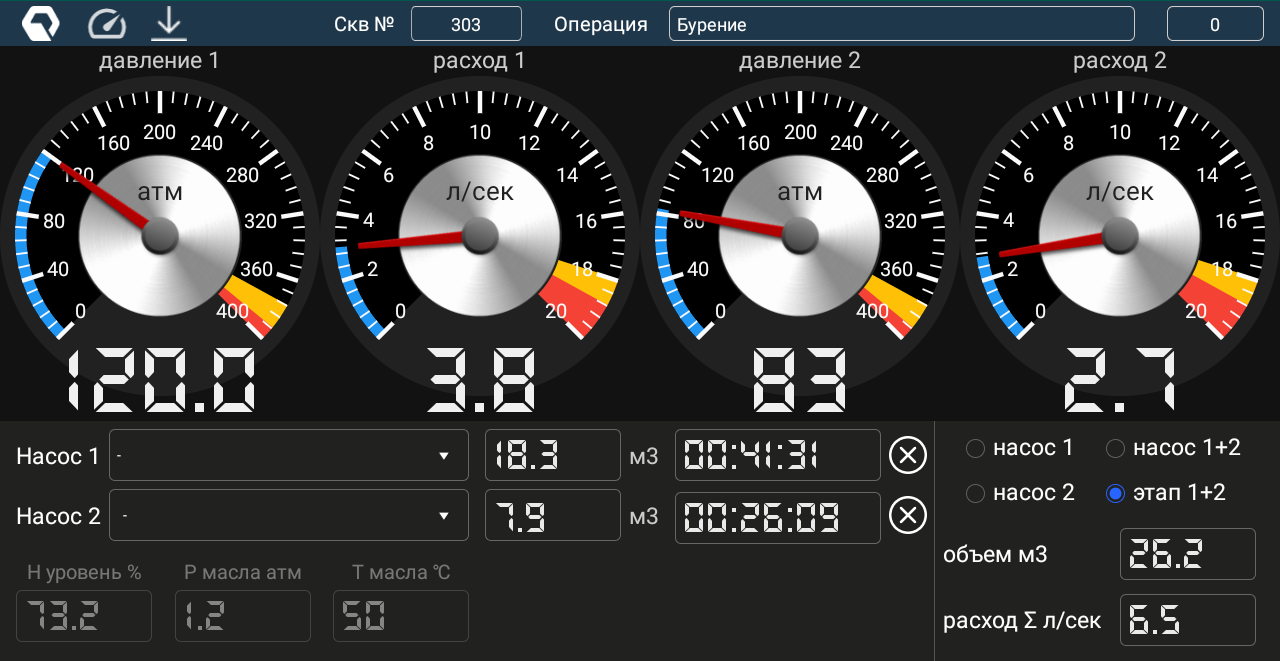

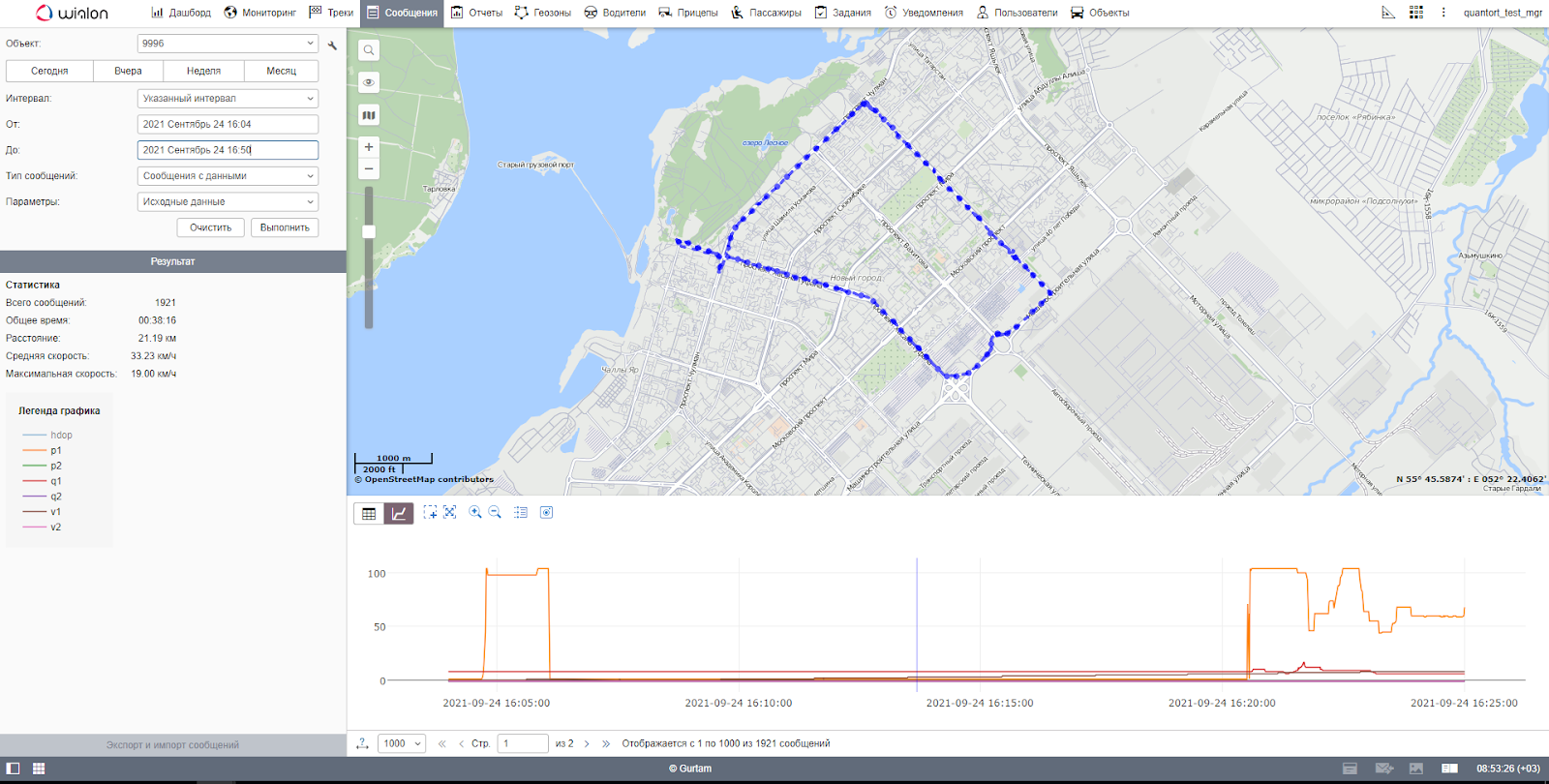

Fuel monitoring system

The module is designed to calculate fuel consumption in any type of machinery, from vehicles to filler trucks

Hardware

Resources

Community

Contacts

Personal account